How to Size an Enphase Encharge Energy Storage System

As an extension of our system design & engineering services, we offer quarterly consulting to contractors, EPCs and manufacturers. One of the questions we hear often through our consulting projects is how to size energy storage systems (ESS) for partial or whole-home backup. In this blog post, I will outline system sizing considerations for one of the fastest growing ESS products on the market, the Enphase Encharge battery.

Step 0: Enphase Encharge requirements

Before doing any calculations we must keep in mind any manufacturer-specific requirements. For Enphase, there are two key requirements to be aware of:

- First, the ratio of PV AC power to battery AC power must not exceed 150%. Or, working backwards, the AC power output of the battery must be at least two-thirds of the AC power output of the PV array. For example, if we have a battery with a rated power output of 10 kW, we can install a maximum of 15 kW of solar PV (10 x 150% = 15). Alternatively, if we already have 15 kW of solar PV, we must install a battery with a power output of at least 10 kW (15 x 66% = 10).

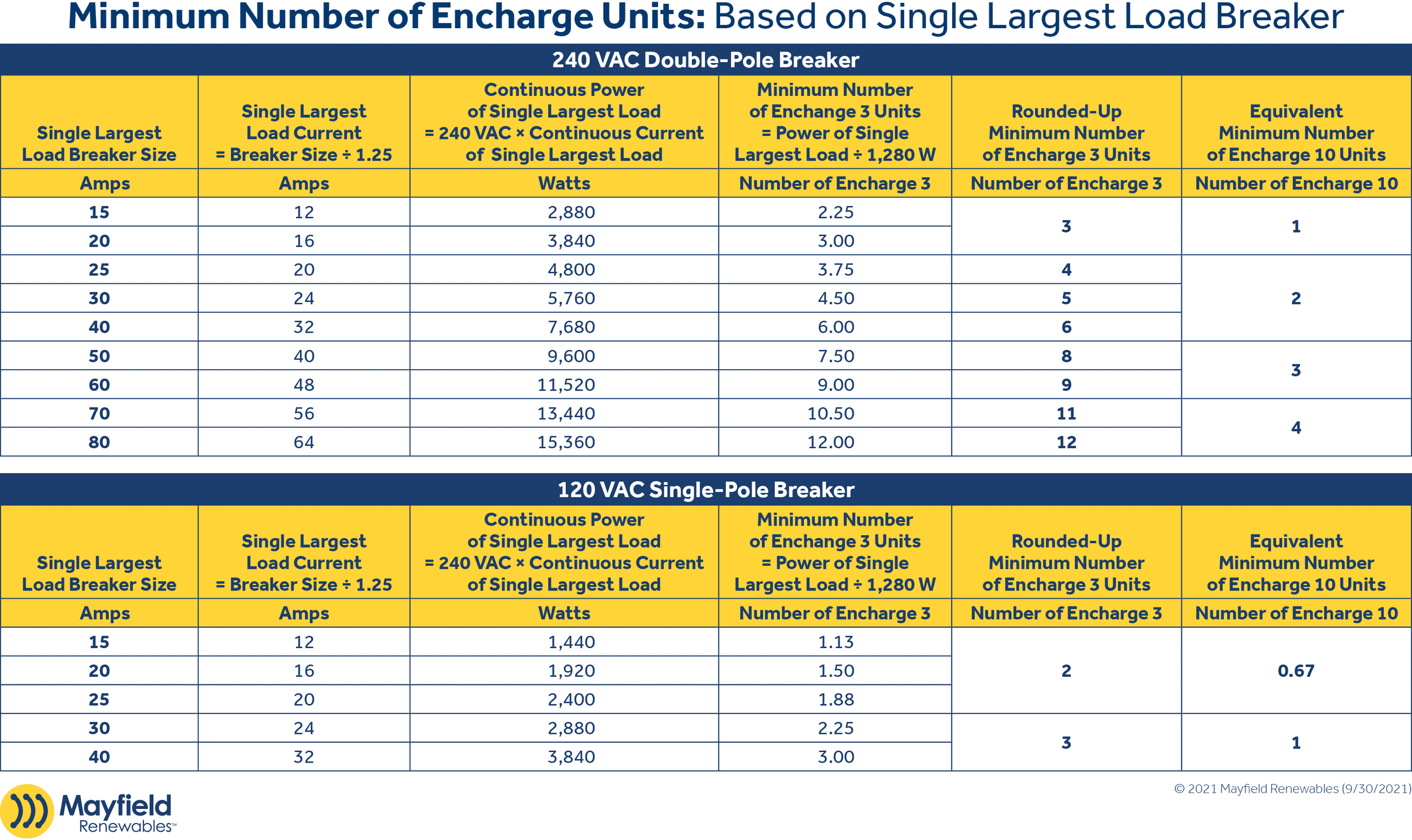

- Second, a minimum of two Encharge units must be installed for whole-home backup (this is not the case for partial backup). In almost all cases, the largest load in the main service panel will exceed the continuous current output rating from a single Encharge (roughly 16 A continuous, or 24.6 A of surge). The ESS must be able to provide adequate current to meet the single largest load and thus two or more Encharge units will be required.

Step 1: Determine which loads will be backed up

Are we backing up the entire home? If not, which loads will be isolated in the case of a grid outage? This critical information must be figured out early in the sales process, as it informs the rest of our calculations.

In both cases, whole-home or partial backup, our Encharge will be sized to meet the largest load in either the main service panel or backup loads panel. Per NEC 710.15(A):

“Largest single backup load must not exceed the power and/or surge capacity of the ESS.”

In other words, the rated continuous output power (in watts) of the Encharge(s) must be equal to or larger than the power of the largest single load in the backup loads panel. The same is true for surge demand.

Looking at the Encharge datasheet, we can see that it has a 16 A continuous current rating at 240 Vac. Multiplying these together nets a continuous power rating, per unit, of 3.84 kVA. To find the surge power, we look at the starting current rating of 24 A and multiply again by 240 Vac, yielding a surge power rating per unit of 5.76 kVA.

Step 2: Perform load analysis

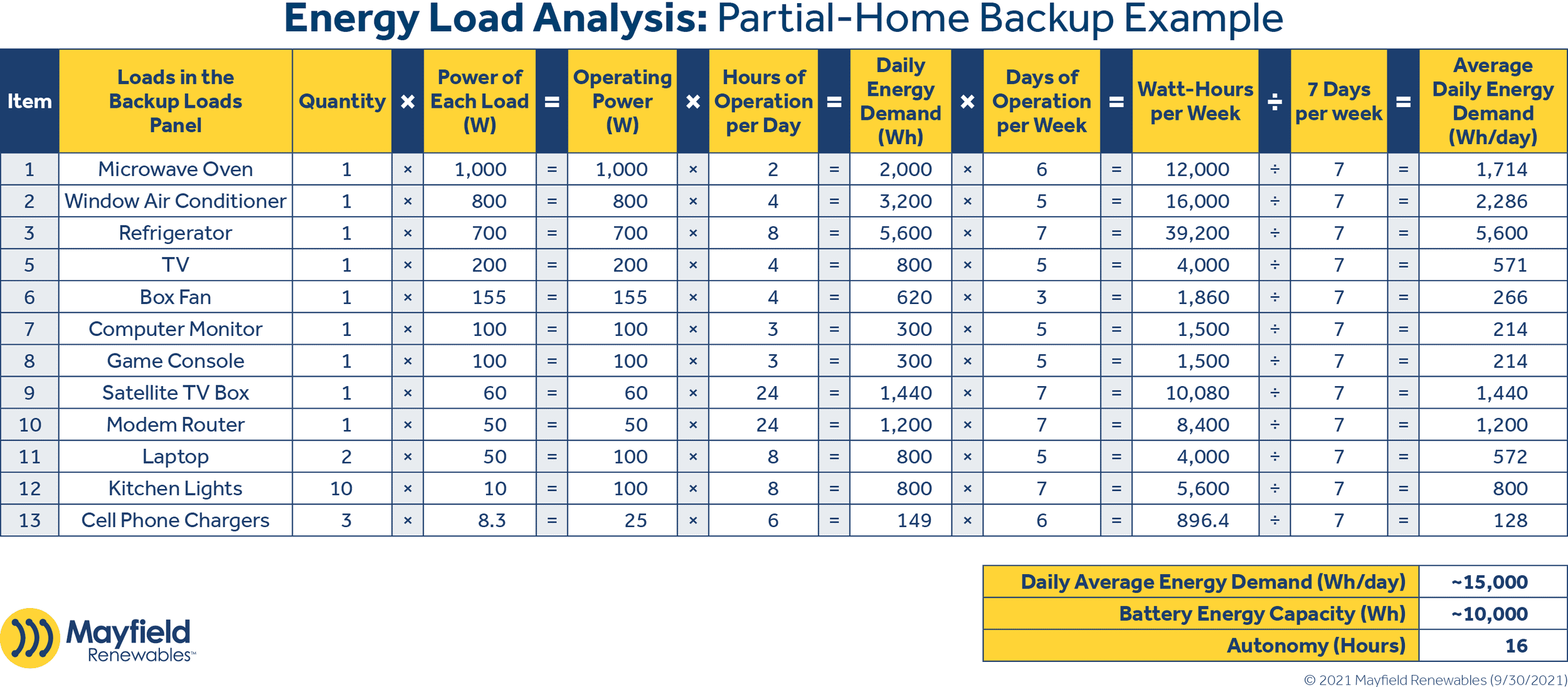

Next, using site data from the utility, we need to build a table of all loads that will be backed up. This data will be used to calculate the battery capacity required to meet onsite energy demands. The same data can also be used to calculate maximum potential hours of autonomy (hours of operation while relying solely on the ESS, without any contribution from the PV array) for the system. See an example of a load schedule below.

Moving from left to right across the table:

- Multiply the quantity of each load (e.g. one fridge, 10 LED lights) times the power of each load to find its operating power, in watts.

- Multiply the operating power by the hours of operation per day to find the daily energy demand in watt-hours.

- Multiply the daily demand by the days of operation per week to find weekly energy demand, still in watt-hours.

- Finally, divide the weekly demand by seven to get average daily energy demand for each load.

Once we have calculated our average daily energy demands, we can sum them to find our total demand and use that figure to calculate the battery capacity needed using the same 150% requirement we covered earlier. For example, if our total daily average energy demand is 15,000 Wh, we work backward to find that we need a battery capacity of 10,000 Wh (10,000 x 1.5 = 15,000).

To find our hours of autonomy, we multiply our newly found battery capacity (10,000 Wh) by 24 hours, then divide that by the daily average energy demand (15,000 Wh). In this case, we calculate an estimated 16 hours of autonomy. Note that this does not account for the onsite PV array. Think of this as a worst-case scenario representing the hours of load coverage by the ESS when fully charged and without additional power contribution from the PV array.

Step 3: Calculating the PV array size and the number of IQ microinverters

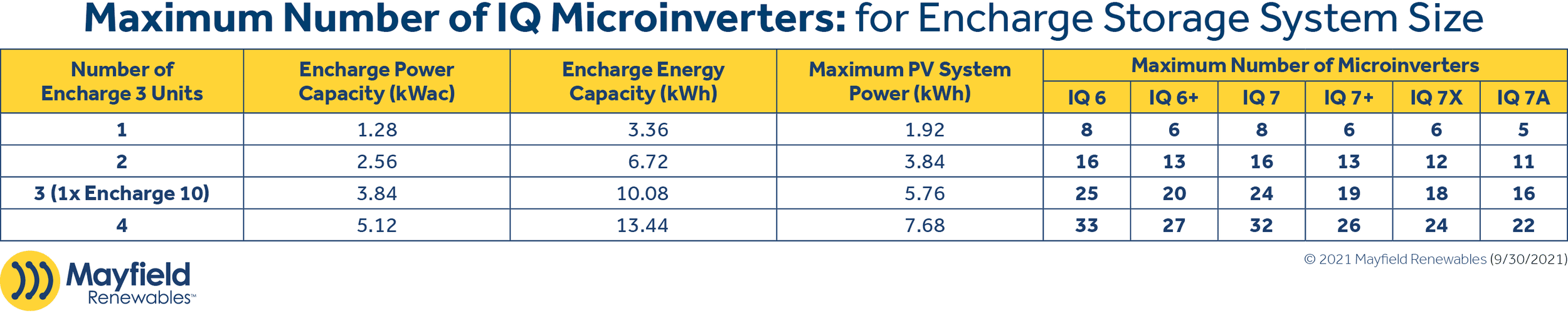

To recap: Up to this point, we have determined which loads will be backed up, performed a load analysis and sized our ESS capacity using that analysis. Once we know our ideal ESS capacity, we can figure out how many Encharge units we need to meet onsite energy demand. All that remains is to size the PV array to complete the system.

As we mentioned all the way back in step zero, the ratio of PV ac power to battery ac power must not exceed 150%. Thus, we can take up to 150% of the ac power rating from our ESS to size the PV array. The Enphase Encharge has an ac power rating of 1.28 kWac per unit. Multiplying by 1.5, we find that we will need no more than 1.92 kVA (ac) of PV per Encharge unit.

Finally, we use our PV array ac rating to calculate the number of IQ inverters for the system. For simplicity’s sake, let’s assume we have a system consisting of a single Encharge unit with a PV array and IQ7 microinverters. The power capacity per Encharge unit is 1.28 kWac, so our PV array must be sized to 1.92 kVA (150% of the battery ac rating). Per their data sheet, IQ7s have a maximum continuous power rating of 240 VA. If we divide our PV array power by the IQ7 power rating (1,920 ÷ 240), we find that we need a maximum of 8 IQ7 microinverters to complete the system. The table below shows the maximum number of IQ microinverters for various system configurations.

That is it! With just a few simple steps, we have sized our ESS and our PV to meet either whole-home or partial backup power requirements and figured out how many hours of autonomy the system will provide.

Author Preston Kahl is a senior PV designer at Mayfield Renewables. To start a solar-plus-storage design project or inquire about project consulting, simply fill out this quick form.