Technical Article

Code Corner: 2020 NEC 705.11 (A) and (B)

In this edition of Code Corner, we're going to talk more about 2020 NEC section 705.11 (A) and (B), where you’ll find the requirements for making PV connections on the supply side. First, when we say “supply side,” we are talking about the supply side of the main overcurrent device, sometimes referred to as a line side tap, even though they are technically supply-side connections. Trying to use that language consistently is important, and now the Code has given us some very good rules on how to make these connections. So let's jump in and first talk about 705.11(A).

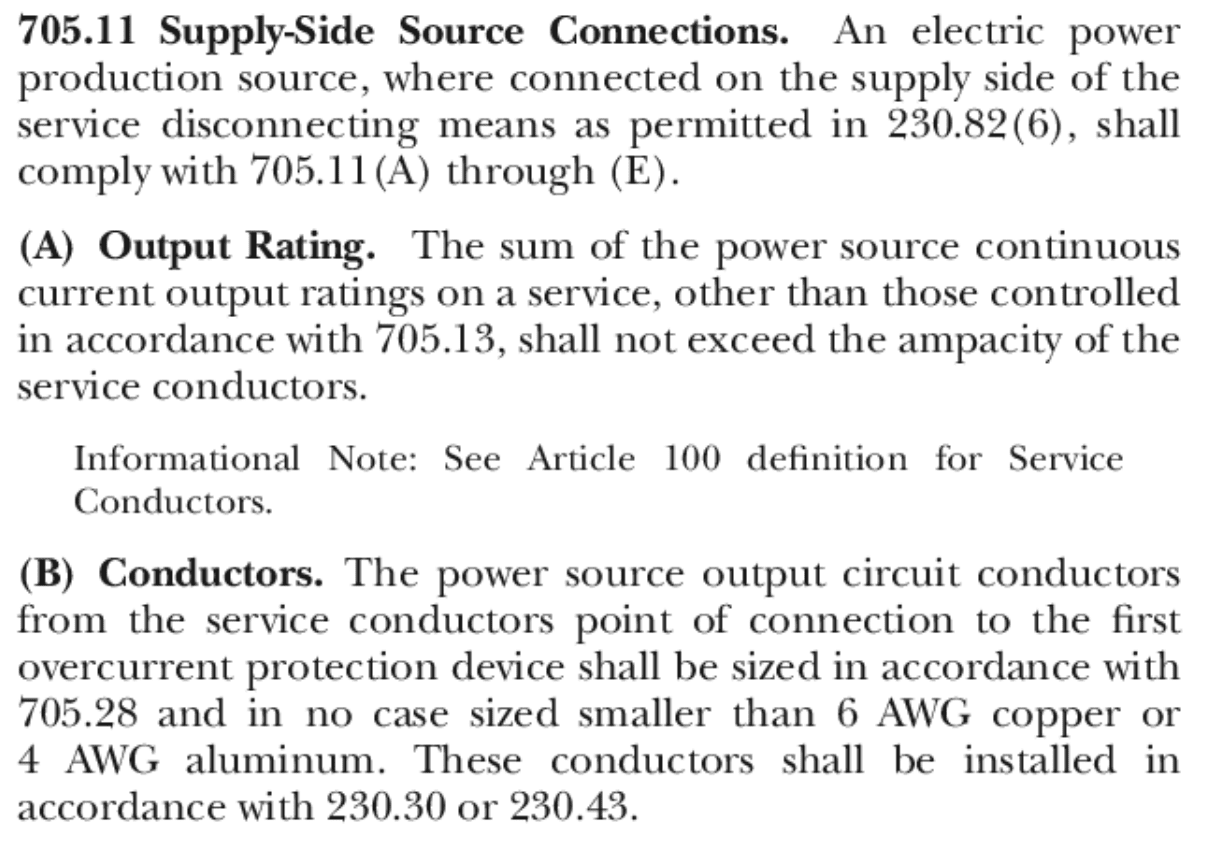

An electric power production source is a generic term, but it's something that applies to our PV systems. If it's connected on the supply side of the service, then we have to go through 705.11. 705.11(A) says that the sum of all of the power sources’ continuous current output ratings on a service, other than those controlled by a power control system. (That's defined in 705.13, but we're not going to cover that in this article.) We're going to discuss traditional PV inverters connected to the supply side of a main breaker/disconnect. The sum of those power sources shall not exceed the ampacity of the service conductors.

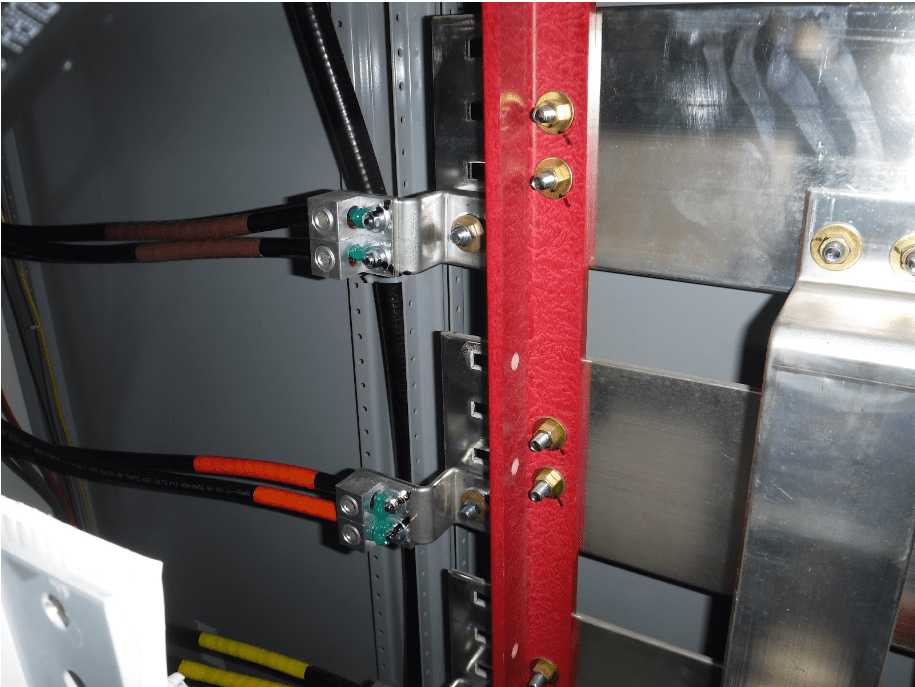

If you have a PV system you're connecting to a service, you can't exceed the rating of those pre-existing service conductors.. It’s basically the same as what we're sizing our output circuit for (the inverter output conductors), but it's just a different reference than section 690. Finally, 705.11(B) requires the conductors to be in no case smaller than 6 AWG copper or 4 AWG aluminum. A lot of times your supply-side connections are done on larger commercial systems, so this is going to be a moot point, but there are cases where you'll do a supply-side connection on a residential application.

If it's a small system with only a 30 or 40 A overcurrent device, you're going to be oversizing wires, but it's a short run so, it's not a huge cost implication. If I have a commercial application with a number of inverters that you’re combining together in a single AC combiner panel, which then goes through a fused disconnect, it’s a supply-side connection. The sum of the continuous currents of the inverters can often exceed the rating of the service, so you should always check and see what those conductors are rated for. You can start by looking at the main breaker/panel; you also need to look at those conductors because that's what you're making that connection to. Sometimes, that requires checking with the utility for service conductor ratings, so you can make sure that you're not putting too much amperage on those.

Overall, if you have a 1,000 A service, a 1,000 A panel, and a 1,000 A breaker, you’re going to have 1,000 A conductors. As long as you are up to, but not exceeding that, you can have interconnections like that, like in the image above, where we have 800 A on a 1,000 A service. This is actually a great way to get more PV onto a building or into a service than would be possible going through a load-side connection. It allows for putting in a bigger system and connecting with the utility.

Here’s an image for 705.11(B) below: we have some parallel runs of conductors, obviously larger than 6 AWG. So these are going to be greater than the minimum, per other Code rules, but an image showing we have to have our conductors properly sized. In a future Code Corner, we’ll be discussing these connections, what their ratings have to be, field listings and more, but you should first make sure that your conductors are large enough in order to meet 705.11(A) and (B).

If you have questions on how to ensure your design complies with NEC 705.11(A) and (B), our System Design & Engineering team is happy to help. Contact us to start a project or learn more. You can also find more of our Code Corner videos on the Mayfield Renewables YouTube channel.