Technical Article

Commercial PV Design Considerations

At Mayfield Renewables, commercial PV design is our bread and butter. My coworkers on the design team and I spend our days looking at building plans, load schedules and local Code regulations. Through our collective experience in commercial system design, we have noticed patterns emerging over time. In this article, I describe the key design considerations that go into any commercial system and break them down into four main buckets: authority having jurisdiction (AHJ), utility, building electrical and building structural.

AHJ Considerations

Among the first steps in a commercial PV project is determining the AHJ(s) associated with the project site. The National Fire Protection Agency (NFPA) classifies an AHJ as “an organization, office, or individual responsible for enforcing the requirements of a code or standard, or for approving equipment, materials, an installation, or a procedure.” An AHJ is not a single entity, but rather several different agencies with regulatory power in a given area. In general, AHJs are composed of local or regional offices that oversee fire, safety, electrical and structural programs.

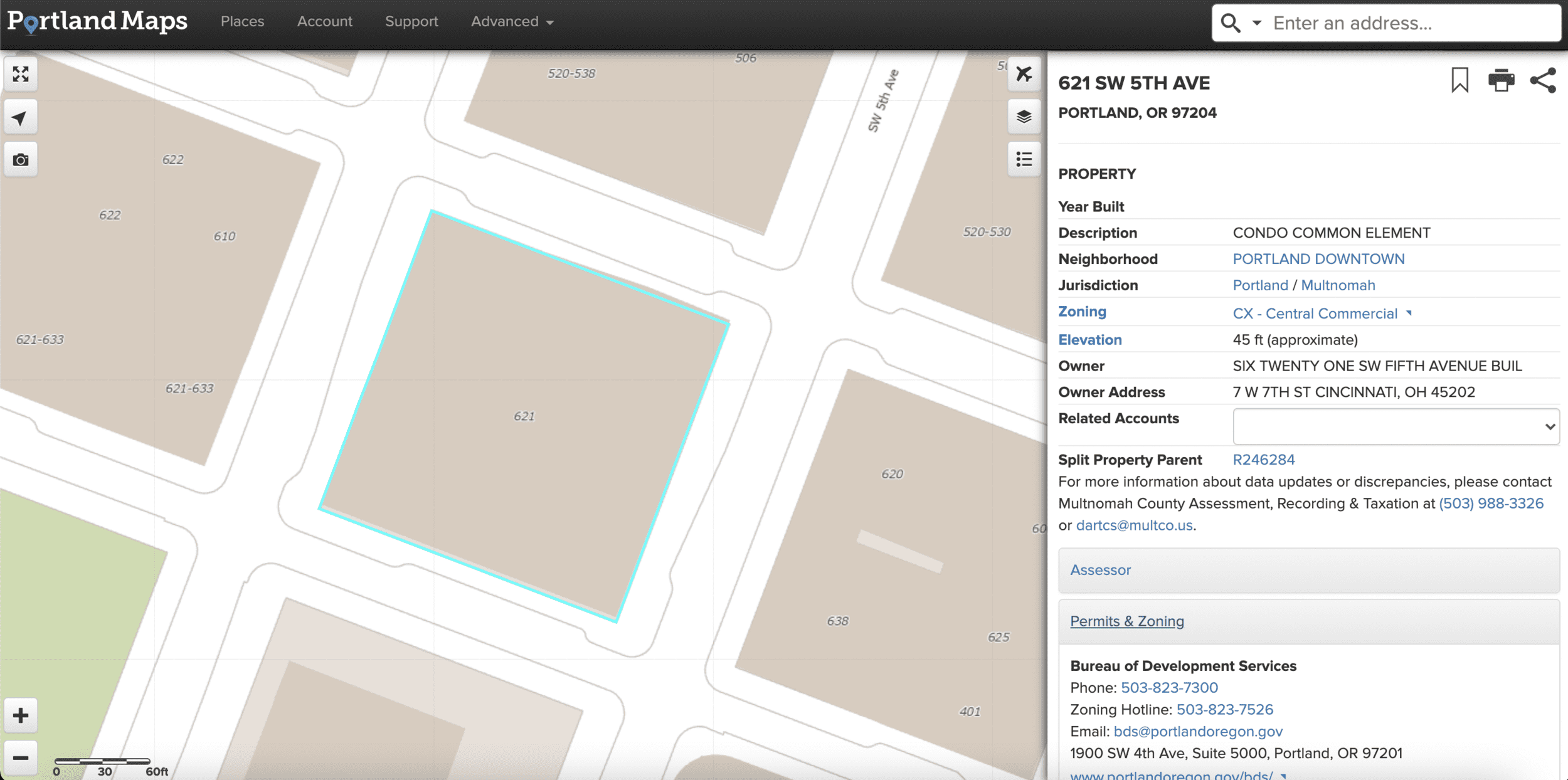

AHJs are not limited to a singular size or scope—it’s possible that a specific site will be under city electrical jurisdiction and county building code, for example. An AHJ could be a state, county, city, township, zone or any other grouping that makes regulatory sense. As you can imagine, this adds layers of complexity to a project. Our preferred method to find project AHJs is to start by asking the building owner. Oftentimes, they will have previous experience with local regulations and can direct you to the appropriate party to handle structural, electrical and zoning issues.

If the building owner does not know the AHJ for the site, online research and calls to local permit departments will be necessary. Some counties and major metropolitan areas will have online tools that track down the AHJ for a given address. In other cases, you may have to reach out to permit offices in the area directly to check if the site address falls within their jurisdiction.

Lastly, once you know the AHJ(s) for your project, it’s good practice to reach out to confirm the following pieces of information:

- Which building, fire and/or electrical code cycle are they following? Some states and localities are still following fire codes from 2009; others may be on the 2021 code cycle and some may have their own specialty codes. Another good resource to check code cycles is from the National Fire Protection Association (NFPA) website, linked here.

- Does my project address fall within any zones or districts with extra (or different) requirements? For example, Historic Districts and design overlay zones tend to have additional permit requirements. In some cases, those requirements may necessitate significant changes to PV array size, shape and location.

- Are there any specific requirements for commercial PV? Some requirements, such as firefighter walkways, engineering review and attachment specifications will influence design choices like racking, flashings and conduit type. Many jurisdictions also follow the International Fire Code. If this is the case, Section 1204 of the IFC will provide details on PV walkway requirements.

- Are there any specific requirements for flat-roof installations? For example, the IFC classifies PV systems as either “Group R3” (residential) or “Other than Group R3.” Based on this classification, certain perimeter pathways, interior pathways and ventilation requirements must be met--with some exceptions based on roof tilt and other factors.

Each AHJ is different and may have requirements you haven’t seen elsewhere. Determining these requirements proactively will save countless hours of research later in the project.

Utility Considerations

Assuming the PV system will be interconnected to the utility grid, it will have to abide by the local utility’s rules and regulations. Much like the AHJ, certain requirements must be met, and those requirements will vary significantly depending on project location.

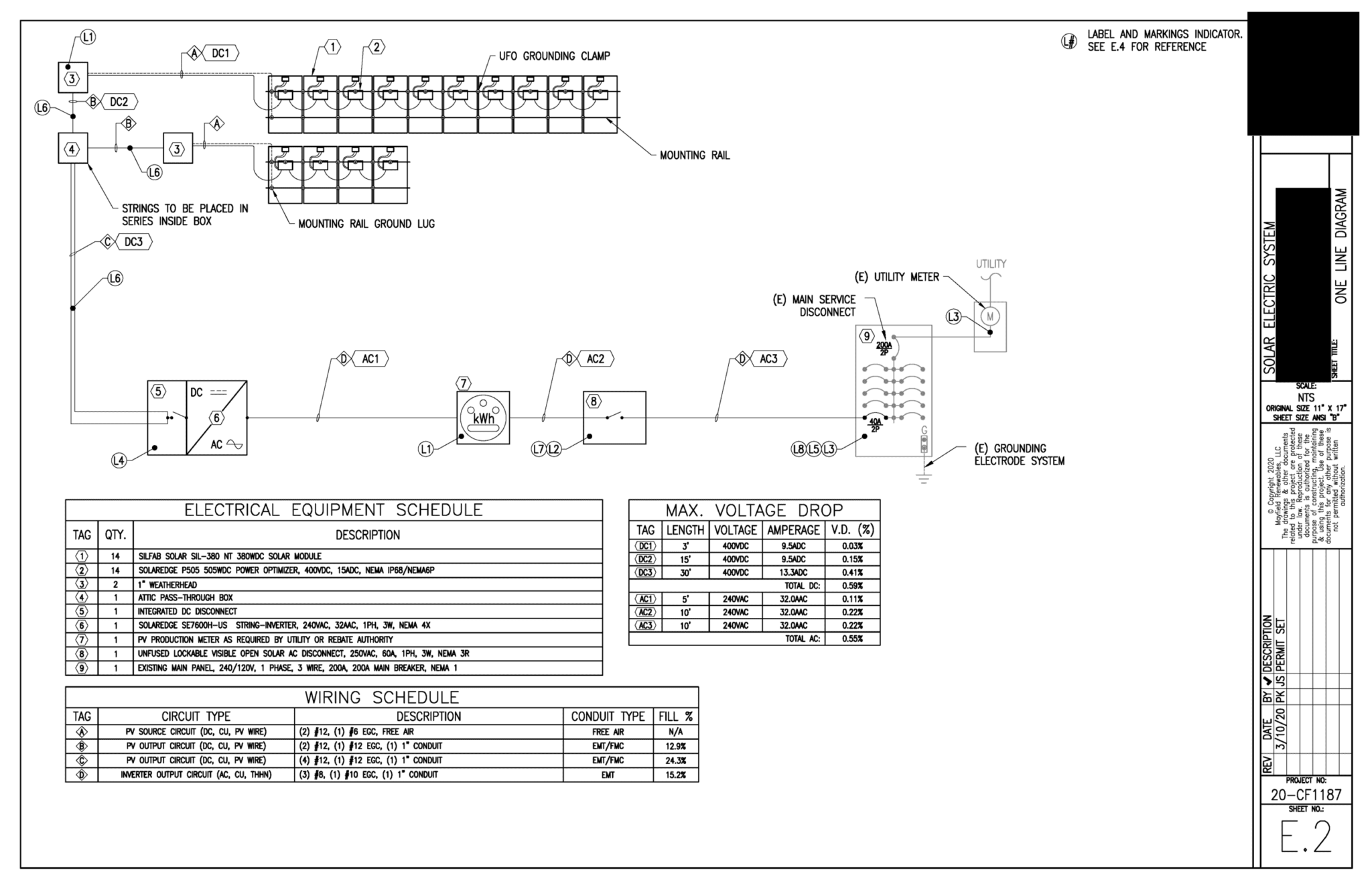

Some utility requirements will be consistent for all sufficiently large commercial PV projects. For example, the utility will need to perform an interconnection study to determine whether or not the grid within the immediate vicinity of the project can handle extra backfed power stemming from the PV array. In most cases, the utility will request a drafted single-line diagram and site plan for the array in order to conduct the study. With the single-line diagram in hand, the utility will examine the local feeder and any other PV generation sources in the area. The project may be not approved at all; conditionally approved with some customer-paid upgrades to the local system; or approved as is. This stage must be completed before moving forward. Failure to obtain utility interconnection approval early in a project can lead to major hurdles and changes later on, or even bring the project to a halt.

After interconnection requirements are met, it’s worth your time to inquire about utility-specific regulations about net metering, export limitations and system disconnects. Some good questions to ask include:

- Is net metering allowed? If so, what is the buy-back rate? This could greatly impact project ROI, often the most important consideration for a commercial system owner.

- Are there any export limitations? In some cases, the PV array must not export to the grid. This again can affect ROI because the inverters will only produce power when the power will be used on site. In other situations, the system may be required to be sized to produce only up to the service usage on a monthly or yearly basis.

- Is a system disconnect required? If so, what type of disconnect is required, and where must it be located? In many cases, a disconnect(s) is required when the system size is above a certain threshold. If required, the disconnect(s) normally must be within 10 feet or within sight of the meter. Although there may be an exemption process, this can add time and may or may not be approved. As a money-saving alternative, check if the main breaker of the AC combiner panel will satisfy this requirement.

- Is a solar energy production meter required on site? This will always be the case for feed-in tariff projects. Occasionally, a production meter may also be required to meet local incentives or specific utility requirements.

Electrical Considerations

Now that we know our zoning, permitting and interconnection stipulations, let’s start looking at the actual building or facility in question. What does its existing electrical system and load profile look like? What are the goals of the solar array? What electrical challenges will we face?

The first item on the checklist for this section is to assess the existing electrical equipment on site. Have an electrician visit the site early in the project, if possible, to catch issues proactively--don’t wait for the inspector to find them post-installation! The status of the existing electrical equipment will determine any interconnection limitations and could provide an opportunity to install newer equipment that is more appropriately sized for the solar array and the building.

In general, older equipment can be a red flag. Older busbars, for example, may be sized too small to handle backfeeding from PV, or may even need to be replaced for safety reasons completely unrelated to the PV system. For newer buildings, performing an equipment check is still necessary in case of any unpermitted work, changes required to bring the equipment up to today’s Code standards, or upgrades for equipment that is not conducive to solar PV such as breakers that cannot be backfed. If there is not adequate space in the main service panel for a PV breaker, you may have to investigate other interconnection options such as a panel upgrade, PV system downgrade or subpanel installation. Proper due diligence at the early stages of a project will illuminate problems well before the system is designed, installed and inspected, leaving ample time to make adjustments and change orders.

The other, increasingly ubiquitous consideration is whether or not energy storage will be included as a part of the PV system, or if the facility owner plans to add an energy storage system (ESS) later on. Storage integration will oftentimes impact the system point of interconnection, as the possibility of current or future energy storage can make it impossible to do a supply-side connection. Even if storage isn’t within the immediate project scope, planning ahead for later storage integration will save significant time and money.

Structural Considerations

We have determined our ideal system size by this point, so what do we need to do to ensure we can meet those electrical needs in a way that’s structurally sound? What should we check for, and where might we need third-party assistance (engineers or structural reinforcements)? This section mostly deals with the roof, but also with support structures.

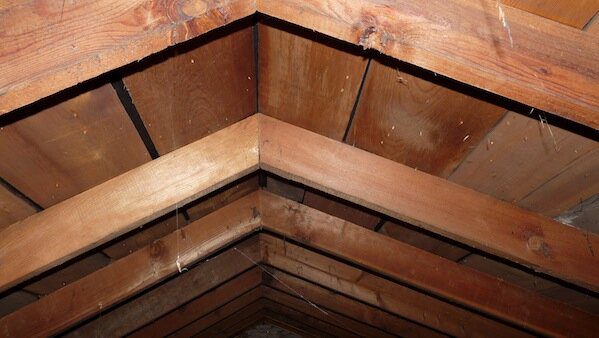

For existing buildings, start by performing an initial site evaluation. Look for any visible issues such as broken trusses or rafters, cracked wood or bowed members. Inquire about the health of the roof--when was it installed and how much life does it have left? Diagnosis from a roofer may be helpful to not only improve the chances of a smooth installation, but also to reduce the liability on the solar contractor if a leak should surface after the solar is installed. A good rule of thumb is to ensure the roof has at least 20 to 25 years of life left.

During the site evaluation, be sure to confirm the type of roof as well. Not all commercial flat roofs are the same; they may be built-up; PVC/TPO membrane; standing seam; tar and gravel; or one of many others. In our experience, installation will be easiest on roofs that are standing seam or PVC/TPO, which generally require fewer penetrations.

The structural supports for the roof must also be checked and, ideally, photographed during the site evaluation. For example, are there rafters or trusses? Is the building stick-frame? Will seismic upgrades be necessary? Most commercial projects will require engineering, for which all of this information will be useful.

Next, confer with the building owner to see if the building was fully engineered. If so, the AHJ should have a stamped plan set with roof and support structure details as well as structural calculations. If you are involved before the building has been fully designed, share the final PV system weight and dimensions with the building engineer. The engineer may need to do additional point- and dead-load calculations to satisfy AHJ requirements for a PV building permit, but if they have this information early, it can save headaches later by ensuring the proper loading is added into their design.

Lastly, consider both installation and O&M safety measures when evaluating the roof space. Centrally locate any equipment that may need service (e.g., combiner boxes, inverters, etc.) whenever possible to ensure technicians will be far from the roof’s edge.

Commercial PV systems are complex. Designing such systems requires a thoughtful and thorough approach. Proactively gathering important pieces of information will save countless hours of research, costly change orders and avoidable surprises at final inspection. Of course, all projects are unique and will present their own challenges, but we hope that this guide will help steer your commercial design efforts, leading to more profitable jobs and happier clients.