Technical Article

Comparing Central vs String Inverters for Utility-Scale PV Projects

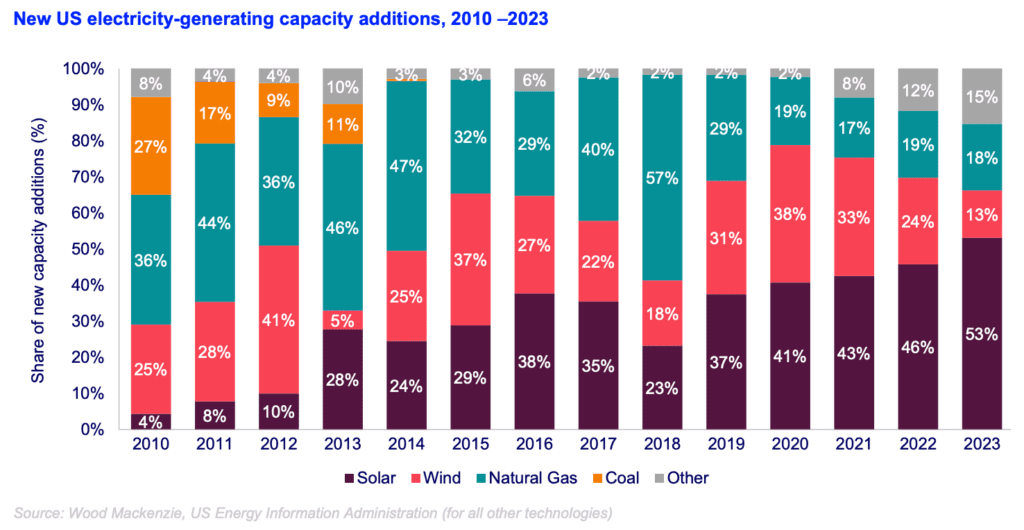

The utility-scale PV market is maturing. Last year, 22.5 GW of utility-scale PV was installed in the US, a 77% jump from 2022. Solar PV accounted for over half (53%) of all new electricity-generating capacity additions for the first time ever. That fact bears repeating: the majority of the new power sources on the grid last year were large-scale solar plants.

As renewables gobble up grid capacity, utility-scale developers are pressured to deliver high volumes of reliable, cost-effective installations. This is a massive opportunity and a considerable challenge. On one hand, the list of viable utility-scale technologies is longer than ever and continues growing. On the other, PV systems are being asked to do more and more. Energy storage attachment rates are on the rise, utilities are demanding advanced grid services, and the availability of “ideal” plots of land is dwindling.

Choosing the right technology for each project is hard. This article will overview perhaps the most essential components in a PV system, inverters, and compare the two main options dominating today's utility-scale market: central and string inverters.

What are central and string inverters?

There are three primary tiers of PV inverters: microinverters, string inverters, and central inverters. Since microinverters are not rated for utility-scale voltages, we will largely ignore them in this article.

String inverters convert DC power from “strings” of PV modules to AC and are designed to be modular and scalable. Smaller string inverters may have as few as one input, with one PV string per input. Larger string inverters can handle many string inputs. In both cases, string inverters will likely have integrated maximum power point trackers (MPPTs) on their input (dc) side to boost array performance at the string level. Newer string inverter models have upwards of 12-15 MPPTs and can handle dozens of PV string inputs.

Note: A “string” is any series combination of 2 or more PV modules. For utility-scale systems, strings often consist of 20-30 modules installed in series.

String inverters have historically been more common at the residential and commercial scales, where string-based designs with MPPTs are effective at maximizing energy harvest from arrays with partial shading, multiple orientations, or undulating terrain. However, recent technology improvements have boosted string inverter power densities, making them more competitive with...

Central inverters are designed to centralize power flows and convert large quantities of power from dc to ac in a single unit. The inputs to central inverters are most often combined dc circuits from many (or all) strings in the array that feed a small number of integrated MPPTs.

The likelihood of encountering a central inverter on a project increases with project size and age. Utility-scale projects above ~10 MW are the most common application today. Large C&I and smaller utility-scale projects from just a few years ago are likely to have central inverters as well, for reasons we’ll touch on in the next section.

An Abbreviated History of PV Inverters

The first PV inverters were developed in the 1980s as a spinoff of drive system technologies. At the time, all models could be considered central inverters rated to handle no more than a few kilowatts. As with any new technology, early iterations were far from perfect. Ironically enough, the drawbacks of early central inverters (mismatch losses, inflexible system design) led to the development of module-level microinverters.

The PV inverter market of this era had two bookends: microinverters for residential and small commercial projects and increasingly large central inverters for everything else. The first generation of string inverters was developed in the mid-1990s to support projects that were not especially large or small. Initially designed for a single string input, early string inverters were viable for residential and commercial applications but struggled to scale up.

With the groundwork laid for a three-tiered inverter market, the ensuing decades were spent refining each technology. Sometimes, innovation was driven by codes, standards, and AHJs (rapid shutdown and UL 3741), and other times by manufacturers themselves (anti-islanding and grid-forming capabilities).

That brings us to today, where the lines of the three-tiered market have blurred. Microinverters and other module-level power electronics can be found on residential rooftops as well as commercial systems. Central inverters are installed in large commercial and utility-scale systems. String inverters are designed for all system sizes.

Central Inverter Benefits

Central inverters are large — in the 1-5 MW range per unit. Most, but not all, 10+ MW PV projects operational today will have one or more central inverters. Some of the reasons for central-inverter dominance at larger scales are as follows:

Lower capital expenditure (CAPEX): While string inverter costs have come down, central inverters are usually cheaper upfront (in dollars-per-watt). Contact your inverter manufacturer for the latest pricing estimates.

Fewer equipment areas: Developers will inherently need fewer central inverters than string inverters for the same overall project capacity, leaving more space for the PV array and less for inverters and balance of system components.

Lower perceived risk: Central inverters are more mature than string inverters. Many examples of central inverters operating for over a decade on utility-scale plants exist. Developers tend to stick with known quantities even when comparable new substitutes are available.

Simplified system design: Designers have much to consider when designing a utility-scale system. Generally speaking, the fewer components, the fewer mounting configurations, labels, wire sizes, protection mechanisms, equipment areas, and access points are required.

String Inverter Benefits

String inverters are physically smaller than central inverters, but the gap in their power output is narrowing. Currently, developers can source string inverters rated for upwards of 350kW per unit. Many string inverter manufacturers offer skidded or cluster-mounted solutions that co-locate hundreds of kilowatts of string inverters into a “virtual central inverter” configuration. Some utility-scale developers are switching to string inverters due to:

Lower operational expenditure (OPEX): A smaller form factor means smaller parts, shorter spare parts lists, and simpler repairs. No special training or heavy machinery is required to repair most string inverters.

Improved system-level resiliency: Imagine two sites – one with a 5 MW central inverter and another with twenty 250 kW string inverters. If the central inverter fails, the entire site goes offline. If one string inverter fails, 95% of site production continues unimpeded.

Flexible system design: Modular string inverters open many doors for system layouts. Inverters can be distributed at the end of array rows, clustered in “virtual central” arrangements, co-located near the point of interconnection, and anything in between.

Increased energy harvest: String inverters with multiple MPPTs will produce more power. This effect is more pronounced on sites with undulating terrain, differing array orientations, and dusty or shady environments.

Conclusion

The answer to almost any PV system design question is “it depends.” When selecting an inverter for a utility-scale system, there is no right or wrong answer; there is just a range of tradeoffs to consider. Is minimizing CAPEX more important than design flexibility? A central inverter may be what you need. Is your site uneven, and is your lifetime O&M budget limited? It’s worth looking into string inverters.

More grid-tied PV was installed than any other generation resource last year. As growth continues and the inverter market matures further, developers will have more and more options to choose from. Determine the priorities and constraints for each project and use those parameters to select the inverter that makes the most sense.

Are you looking for an engineering partner who can navigate consulting on product selection and value engineering opportunities? Reach out to discuss how we can support your team today.